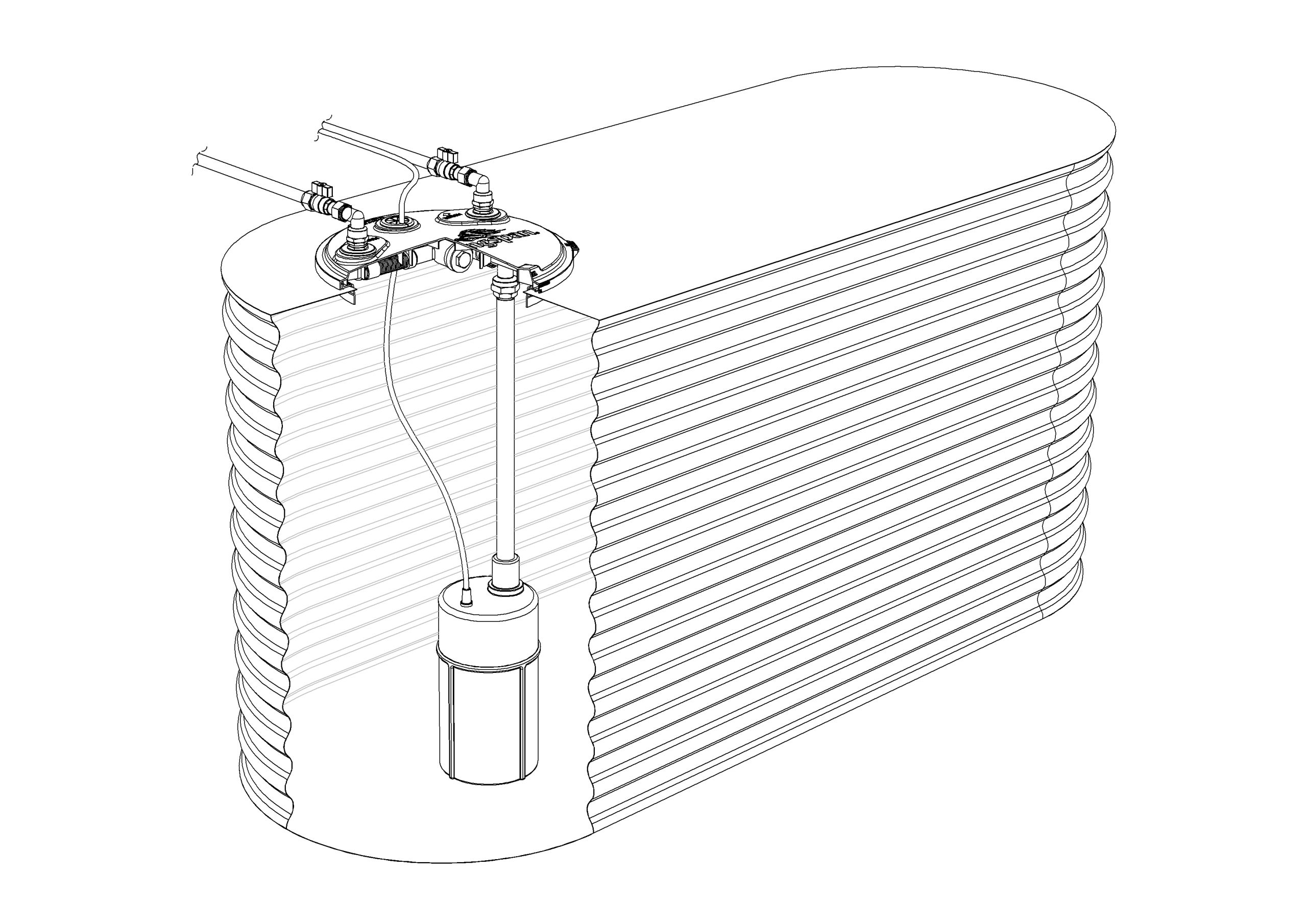

We operate throughout Australia. Our Skilled Service Team and Staff also arrange on site liner Installation. Liners may be manufactured in One Piece, or multiple sections and site bonded depending on the tank configuration or if the tank includes internal supports or braces.

All manufacturing and site work follows a rigid Installation and Testing plan as part of our accredited management system. Where required we comply the requirements of AS2304. Liner selection considers Temperature of stored fluid, Specific Gravity, fluctuations, Elongation, Shrinkage, and environmental conditions such as humidity and UV for tanks with an open top.

Our liners are compliant with AS4020, PVC Liners Potable/Non-Potable, Reinforced RPVC Liners, XR3 Potable material, XR3 Industrial, XR5 materials and Butyl rubber. We have a Liner material for the majority of water sources, applications and to suit the Water Chemistry. Provided we have a Water Analysis, the Tank Empty and Fill cycle information and purpose of stored water we are able to recommend and select the correct material for the right application and help maximise the service life of your Tank.

Kingspan have a network of liner material suppliers, manufacturers and are complimented with our own in-house liner manufacturing facilities.

Our liner capabilities under our service division extend beyond replacement liners for our own products. We provide liners for most modular bolted panel tanks, square tanks, and concrete tanks.

Our liners are manufactured in Western Australia and Brisbane under factory-controlled environments and our ISO 9001 certified management system.

Your liner may be approaching the end of its service life and potentially in need of replacement. For liner Tanks, the liner membrane is the only water containment. Depending on your tank type, application, existing liner material, frequency of servicing and cleaning, your liner may be approaching the end of its intended service life. We also offer liner inspections and reports and can undertake inspections with tanks empty or full using one of our Remote operated vehicles. For Fire and related Tanks, As2304 stipulates a minimum liner design life of 10 years. A leaking liner may cause countless damage to the tank, its surrounds and beyond. A leaking tank over just short-term period can cause extensive corrosion to the tank which may significantly increase the cost of a liner replacement and corrosion repair.

For more information, call our service team directly at 1300 736 562 or email service.au@kingspan.com.

Send us your enquiry today with the following details and we will contact you to discuss options and prices.